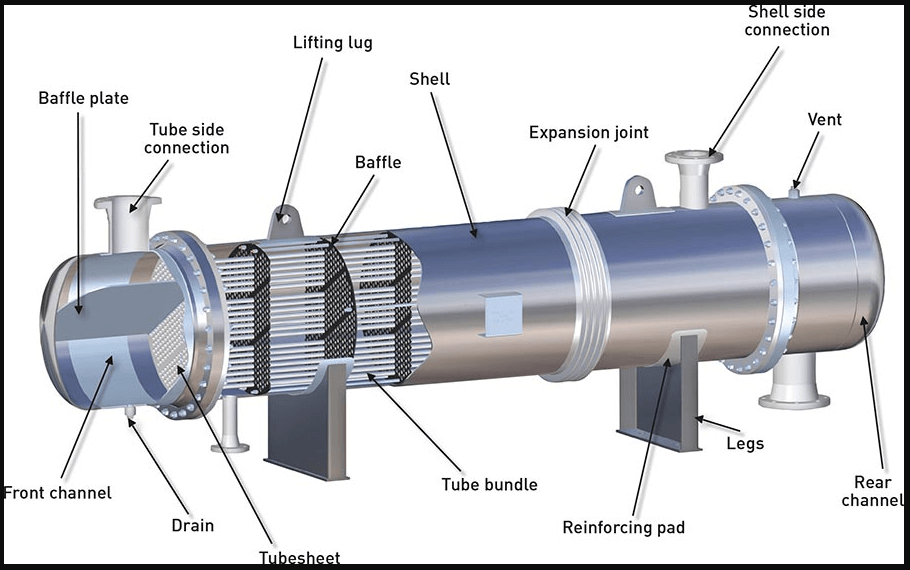

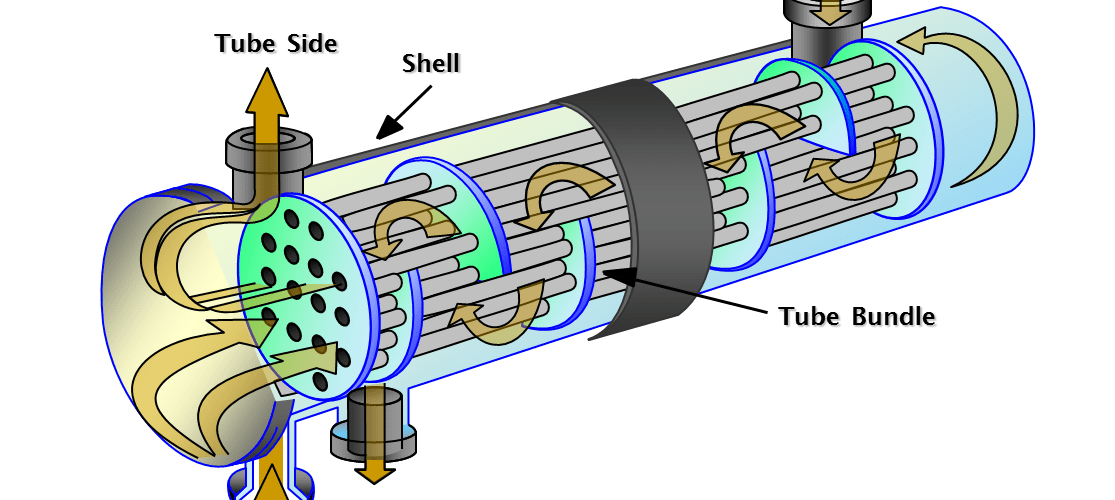

heat quantity. Components of the shell-and-tube heat exchanger 1 Heat exchanger shell 2 Connection chamber 3 Guide chamber 4 Internal tubes 5 Tubesheets 6 Baffles 7 Apparatus seal However, an effective heat exchange can only take place if the temperature difference is sufficient. The greater the temperature difference, the smaller will be the.. Shell and tube heat exchangers are, simply put, a device that puts two working fluids in thermal contact using tubes housed within an outer cylindrical shell. These two integral pathways are usually built out of thermally conductive metals that allow easy heat transfer ( steel, aluminum alloys, etc.). The tubes carry a fluid from their inlet to.

1000 Sq Ft Energy Exchanger Stainless Steel Shell & Tube Heat Exchanger 4923 New Used and

Types of Heat Exchanger according to construction The piping talk

Basics of Shell & Tube Heat Exchangers Arveng Training & Engineering

Shell And Tube Heat Exchangers at Best Price, Shell And Tube Heat Exchangers Manufacturer in Gujarat

√ Télécharger l’image image tube 268395Image tube meaning Saesipjosjljt

Shell and Tube Heat Exchangers Mason Manufacturing

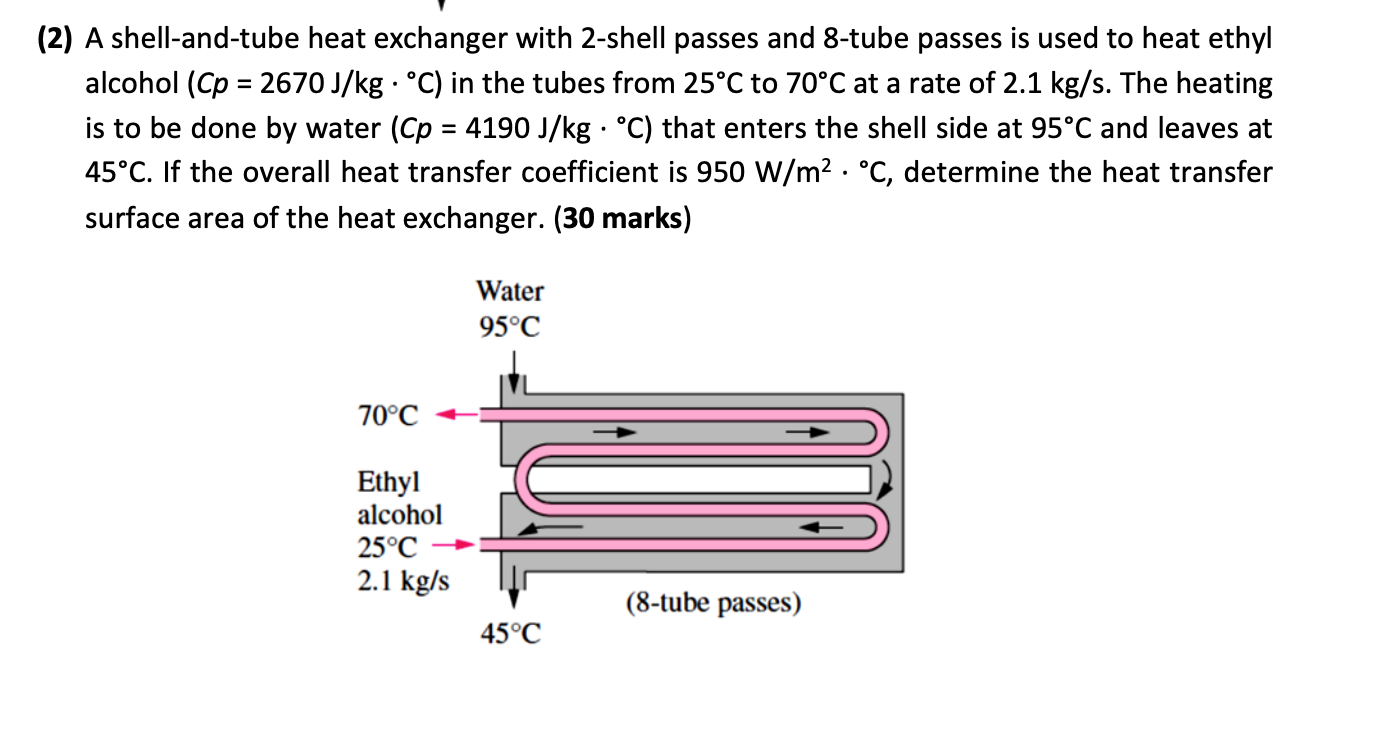

Solved (2) A shellandtube heat exchanger with 2shell

Chiller VS. Heat Exchanger, What Is The Difference And Which One Is More Suitable For You

Shell and Tube Heat Exchanger What Is It? Types, Process

Shell And Tube Heat Exchanger Design Mechanical Design Of Heat Exchangers Water at 2.5kg/s

Tubes Heat 2 Telegraph

Shell and Tube Heat Exchangers Kennedy Tank

Schematic diagram of experimental setup in shell and tube heat exchanger Download Scientific

Shell and Tube Heat Exchanger Explained saVRee saVRee

Shell and Tube Heat Exchanger What Is It? Types, Process

Solved A 2shell passes and 4tube passes heat exchanger

Heat Exchanging Marine Engineering Auxiliary Systems

Shell And Tube Heat Exchanger Shell And Tube Heat Exchanger Exporter, Manufacturer & Supplier

Shell and Tube Heat Exchanger Manufacturers Suppliers

Shell and Tube Heat Exchanger Explained saVRee saVRee

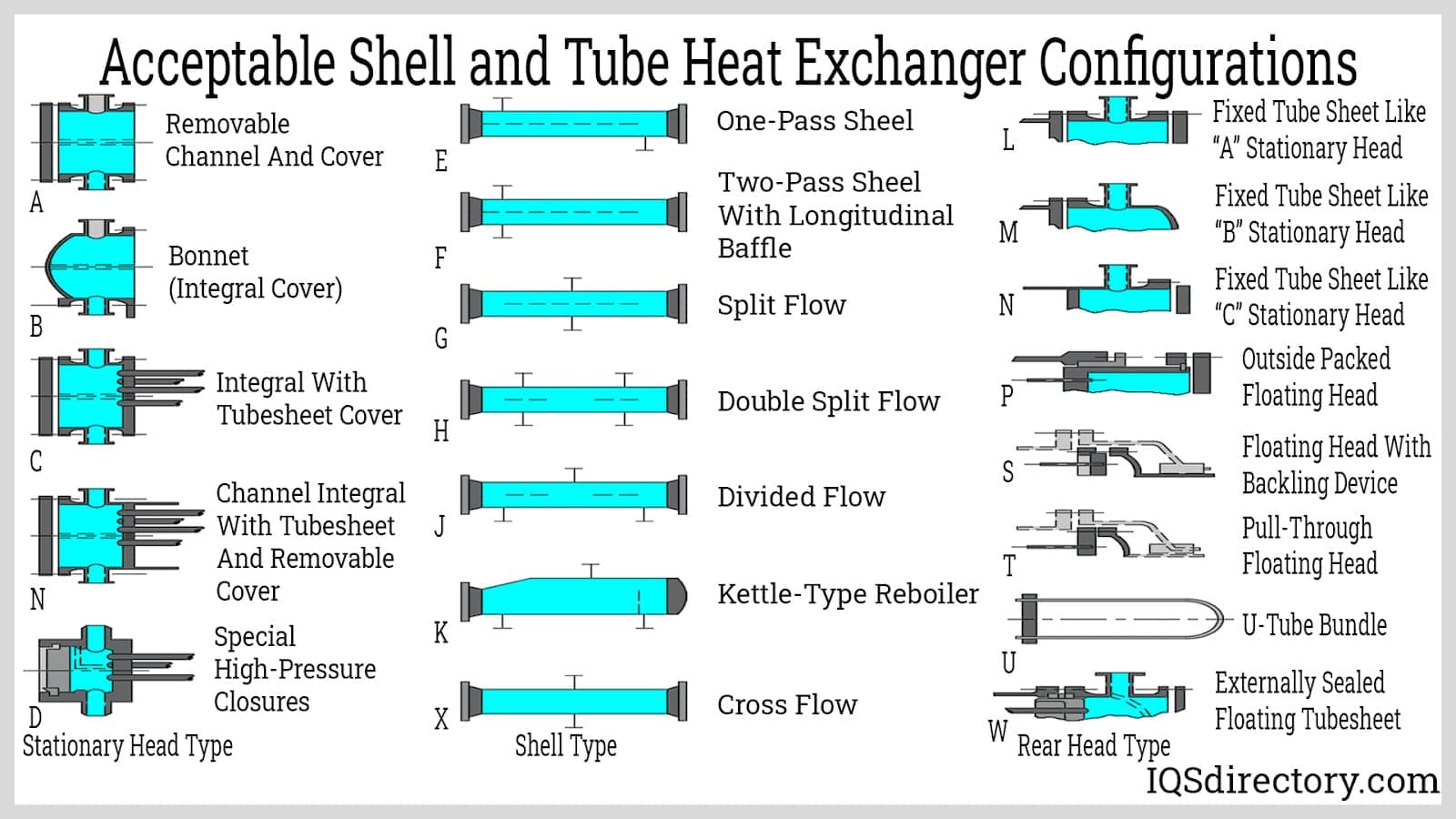

Table 2: Typical fluid Velocities in Shell and Tube Heat Exchanger Design Pressure Drop Consideration. Typical pressure drop values considered for shell and tube heat exchanger design are: For Liquids with Viscosity<1 mN-s/m 2, ΔP=35 kPa; For liquids with Viscosity=1 to 10 mN- s/m 2, ΔP= 50-70 kPa; Liquids without phase change= 70 kPa. The general principles of the mechanical design of the following types of exchangers are given in the Heat Exchanger Design Handbook (1994), and full descriptions of each, are given under the corresponding entries in this encyclopedia: Shell and Tube Exchangers. Air Cooled Exchangers. Plate Type Exchangers. Plate Fin Type Exchangers.